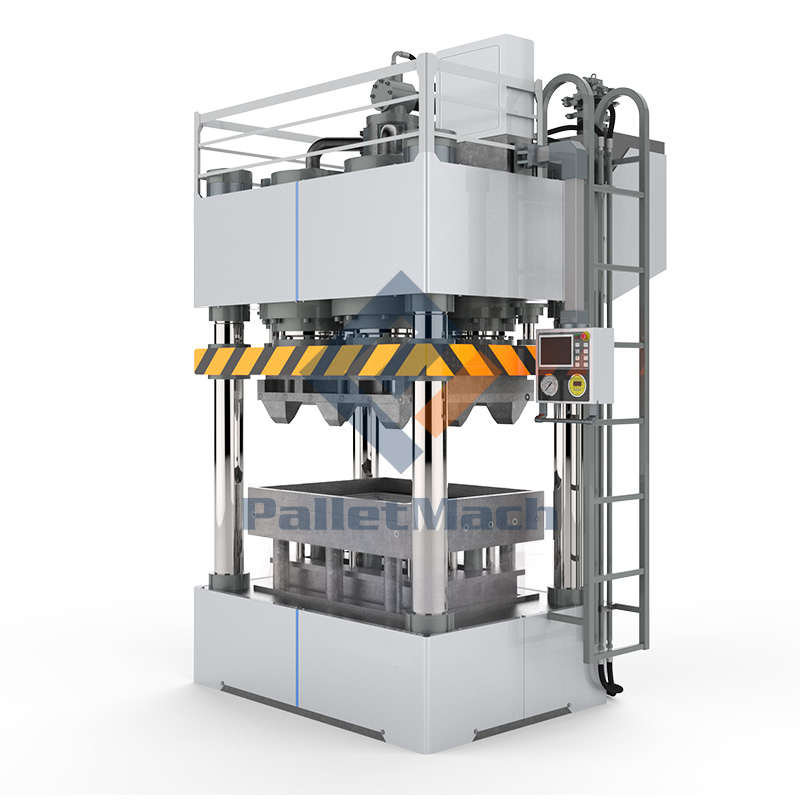

compressed wood pallet machine | presswood pallets machine

The compressed wood pallet production line is a complete set of pallet forming equipment. Our company independently designs and develops this new type of equipment. the wood pallet press machine is the core equipment of the molding pallet production line. The wood pallet press machine can use wood chips, straw, shavings, straw, cotton stalks, etc. as raw materials.

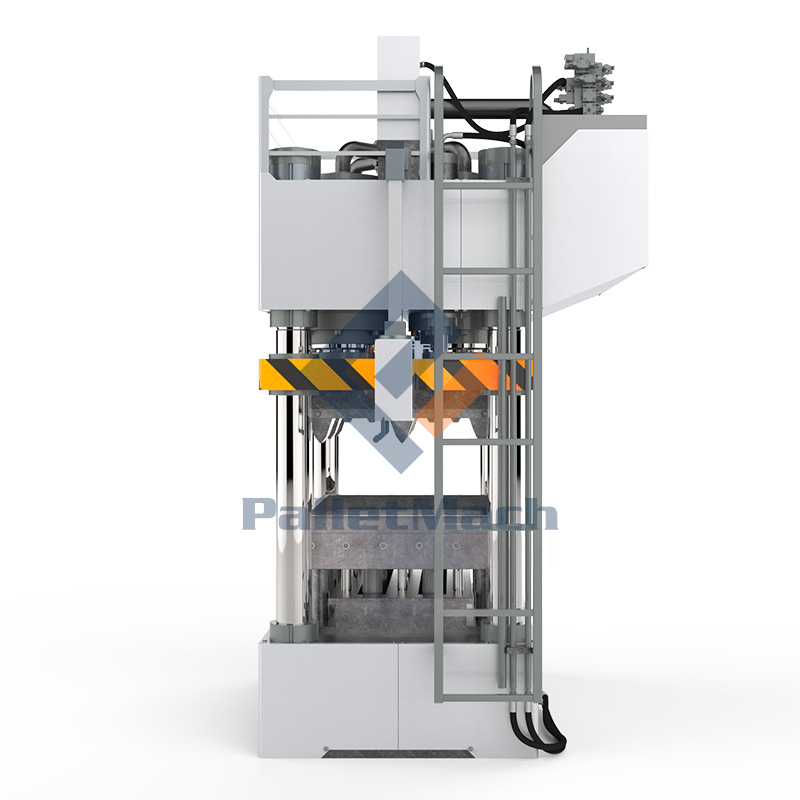

The wooden pallet press produced by our company has a reasonable structure design. It adopts three-way synchronous positioning and can be pressurized in place within 35 seconds. Just spread the wood chips in the mold, operate the work button, and the mold press can automatically complete it.

follow us

Facebook Youtube Linkedincompressed wood pallet machine description

Wood pallet pressing machine from dried and crushed wood waste is used to make the wood pallet which is used for transportation. It adopts sawdust or wood chips as raw material, hydraulically pressed by high temperature up and down into a pallet. The equipment has an independent hydraulic system, steam, or heat transfer oil as the heat source. The equipment is energy-saving, stable, easy to operate, small in area, and no special requirements for the workshop. Can produce various specifications of pallets.

The molded pallet production line is mainly used to produce molded pallets of various sizes and patterns. The production line can use all kinds of waste wood, dead branches, scraps, waste boards, etc. as raw materials to produce molded pallets. It is energy-saving, environmentally friendly, reusable, and output. Advanced is a new type of pallet production line.

The working principle of wood pallet press machine

The raw materials obtained by mixing the glue are subjected to high temperature and high pressure for compression molding. Combining different sizes and different patterns of molds can produce different wooden pallets.

https://youtu.be/4ZsLNRt0dCsRaw materials and pictures of molded pallets

The raw materials of molded products can be small diameter wood, wood cutting residues (branches, branches, etc.) and wood processing residues (slabs, slats, garden wood cores, waste veneers, etc.). It can also be used to cut non-wood materials (such as hemp stalks, cotton stalks, reeds, moso bamboo, etc.). It needs to be crushed to the size required for production before molding, so that the fibers of the molded product are neat and consistent and the product is more beautiful.

the finish product of wood pallet press machine

Single-sided molded pallets are the most common and most popular style among molded pallets. It is made by one-time pressing under high temperature and high pressure in the mold. Because its production process has been in a high temperature and high pressure environment, it has already killed the eggs and harmful substances that may be carried at high temperature, so it does not need to do any fumigation during the export process. Compared with traditional wood Pallet, it is simple and convenient, does not require any processing and presentation of any customs clearance documents.

FQA

1. What is the moisture of raw material for making wooden pallet?8%-10% is better for wood pallet hot press machine to process.

2. How to pack the wood pallet press machine when deliver plant?Wood pallet making machine can be disassembled, the height is around 2.75m after disassembling,

We will use the 40 feet top open container for delivery.