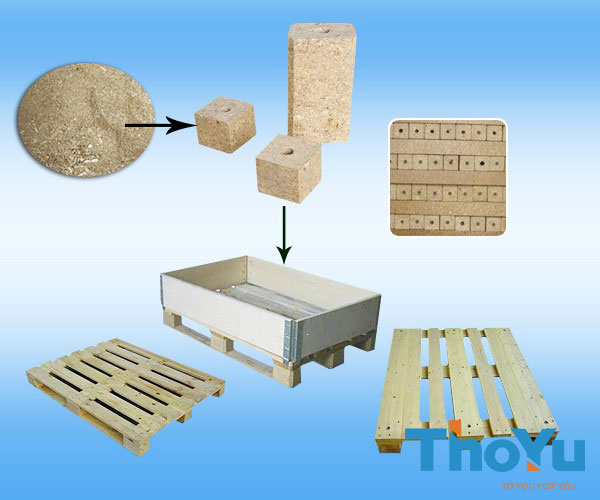

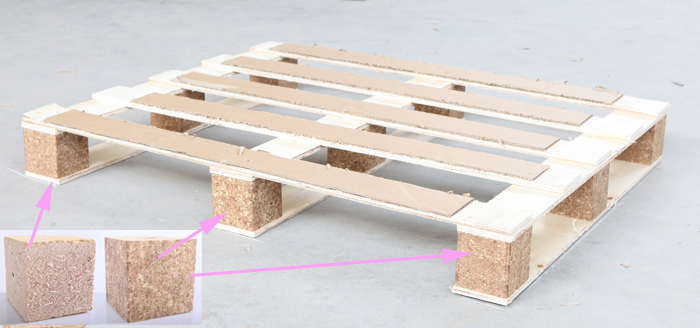

Wood block cutting machine is used for cutting wood strips to wood block. And the pallet block is used to make the wood pallet base, which is for the transportation or storage pallet. Besides, the final pallet block could get the E1 grade. While, the pallet block could be solid without hole in the center, and also could be hollow.

How to make pallet block?

- Hydraulic cylinder provides high pressure and pushes the piston to extrude and mold the materials.

- The heating of the heating plate at the high temperature promotes the solidification and molding of urea-formaldehyde glue.

- Cutting according to certain length (usually around 1.2 meters).

- After cooling, cutting the long wood strips of half-finished products to the final size.

How does Wood block cutting machine works?

wood block cutting machine advantages

- High precision : totally vertical, smoothly for intersecting surface.

- High efficiency: cut blocks in 1800 pieces/hour, can work in 24 hours.

- Easy operation: 1 worker can handle.

- Low cost: little waste in cutting lose.

- Size adjustment: can cut into different size of block.

- Safety: worker no touch to saw in whole process.

- Small occupied area: < 2 m³

Pallet block features

- Free fumigation. Because the pallet block is made by hot pressing, it is free fumigation.

- Pallet block machine could recycle the wood waste efficiently.

- Easy to operate. One person could handle 3 machines.

- Density of final product could get to 550-1000 kg/m3.

wood block cutting machine parameters

| Size (mm) | Weight (kg) | Power (kW) | Dia of saw (mm) | Capacity (pieces/hour) |

| 1600*1200*1300 | 200 | 5.5 | 400 | 1800 |

Pallet block size is 90*90 mm, 90*100 mm, 100*100 mm, and 80*90 mm. If you have special requirements, we could provide customized service. While it is at the range from 75 mm to 145 mm. Besides, one pallet block machine could make two different sizes block.

ThoYu pallet machinery ongoing research seeks to further increase the understanding of the relationships between the design and performance of wood pallets and the entire unit load, to obtain even greater resource efficiencies in the future.

Need a custom box? presswood pallets and cases to your specification:Just send us the size… It’s simple and fast!Get a quote before you order, normally the same working day.

ThoYu provides you semi-automatic and fully automatic wooden pallet production line. What’s more, you also can produce different types of pallet according to your need. At the same time, one set of wooden pallet machineequips with one set of the mold. If you want to produce different pallet, you just change the mold only.

Above all, Thoyu also provides molded plastic pallet machine and wood pallet block machine for you. In addition, we can provide all series of auxiliary equipment, such as wood chipper, wood crusher, wood drying machine, glue mixing machine and so on.