wood pallet block production line|compressed wood block production line

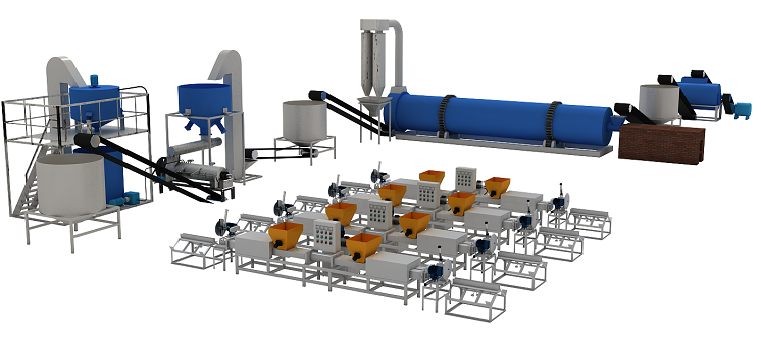

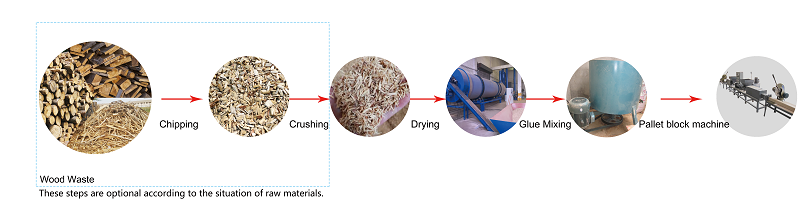

The sawdust pallet block production line is mainly used to produce compressed wood blocks. This machine for production pallet blocks uses waste wood, sawdust, and wood shavings as raw materials. These materials are very common and easy to get in life. The equipment has simple structure and convenient operation and can produce environmentally friendly sawdust pallet blocks. The sawdust pallet block production line usually includes wood chipper machine, wood crusher machine, sawdust drum dryer, glue mixing machine, Presswood block making machine, and so on. Presswood block making machine is divided into single-head wood pallet feet machine, double-head wood pallet legs machine, three-head wood pallet feet machine. Different wooden pallet block machines have different capacities, and customers can choose the right machine according to their capacity requirements.

The introduction of automatic sawdust pallet block production line

We are a professional sawdust pallet block production line manufacturer and supplier with many years of experience. The sawdust pallet block production line is a machine specializing in the production of pallet blocks. It has the characteristics of safety and stability, diverse functions, simple operation, and high productivity. This pallet block manufacturing project can solve the problems of low working efficiency and unstable product quality of traditional wooden pallet block machines, and can greatly improve production efficiency and reduce production costs. The production line mainly uses waste wood, sawdust, and other materials. After being crushed by a chipper and a grinder, it is dried by a dryer and then mixed with glue in the glue mixer. finally, the material is pressurized and extruded in the foot block machine.

Advantages of the wood sawdust block production line

This equipment is a new wood chip pallet block machine production line independently developed by our company based on years of experience in the pallet industry. The pallet block produced by this presswood pallet block is very strong, with a smooth and flat surface, good waterproofness, and long service life. The mold of the wood pallet block machine can be customized according to the specifications and dimensions of the pallet feet required by the customer. The product is free of fumigation, has very little formaldehyde content, and meets international standards. And the raw materials can be various waste wood fiber materials, which are cheap and have a wide range of sources. Before you buy the machine, we can test the materials you want to process.

The composition of the sawdust pallet block making production line

In processing, the processed raw materials are different, and the machines selected for the production line are also different. The wood pallet block production line usually consists of wood chipper machines, wood crusher machines, rotary drum dryers, glue mixer machines, and wood pallet block machines. If the raw materials are logs and large pieces of wood, they need to be crushed with wood chippers and wood shredders first. If the raw material is small particles of sawdust, it can be dried directly, and then mixed with glue to make wood pallet block.

During production, one person can operate multiple machines. If the number of equipment on the production line is large, you can consider using an automated pallet block machine production line. The production line is equipped with automatic conveying, feeding, and mixing devices, which are coordinated and controlled by a PLC controller. It can realize automatic feeding, automatic distributing, automatic mixing, automatic weighing, and automatic glue adding.

The wood chipper machine in pallet block production line

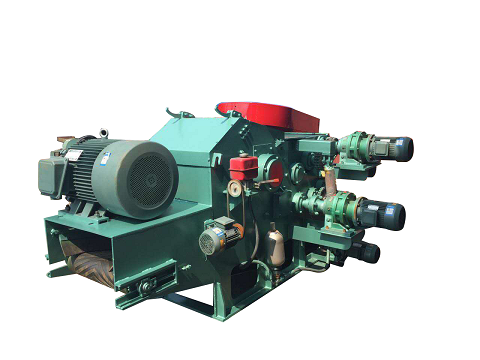

In the production of pallet legs, large pieces of wood cannot be directly used to produce pallet legs. Therefore, a wood chipper is required to chip it first. Wood chippers machines are usually divided into disc wood chippers machines and drum wood chippers machines. Wood drum chipper is mainly used to process logs, trail wood, branches, waste wood, processing residues, etc. into wood chips. After the raw material is cut, it becomes a certain small wood chip, which is convenient for the wood crusher machine to crush.

The working principle of wood chipper machine

The conveyor transports the wood into the inlet of the wood chipper. When the wood comes into contact with the cutting blade of the drum chipper, it follows the high-speed rotation of the cutting blade and is cut by the blade. The cut wood chips are sent out in the cutting chamber by the high-speed steam generated by the blades on the cutting blade. The drum chipper has wide raw material adaptability and convenient operation and maintenance. It is a commonly used machine in wood processing.

The wood crusher machine for pallet block

Wood crusher machine (also called sawdust shredder, sawdust pellet machine) is the special equipment for wood crushing designed by our company according to the needs of processing wooden pallet block after years of research. The whole equipment only needs to be driven by a motor, with low noise, simple structure, low price, stable work, low energy consumption, high output, good quality of processed wood chips, and low processing cost. The size of the sawdust after cutting by our wood shredder is small, and there is no need for secondary crushing. The fineness of the product can be adjusted through the screen. After being crushed, it can be directly transported to the drum dryer machine for drying to remove moisture.

The working principle of wood crusher machine

The wood shredder uses blade cutting and high-speed air impact to break the wood. During the blade cutting and crushing process, the rotor generates a high-speed airflow, which rotates with the cutting direction of the blade, and the material is accelerated in the airflow and repeatedly impacted to crush the wood. The crushed material flows out after passing through the screen.

The rotary drum drying machine in pallet block production line

Our company’s drum dryer is special equipment designed for drying wood chips, sawdust, wood flour and other materials for the production of wooden pallets block. It has the characteristics of large drying capacity and energy saving. The rotary drum drying machine is mainly composed of rollers, lifting plates, guide plates, motors, blowers, heating devices, etc. When producing wooden feet, too much moisture in the wood chips will seriously affect the quality of the wooden feet, and a rotary dryer is usually needed to dry the materials. The effect of drying directly affects the quality of the glue mixed by the glue mixer in the next step.

The glue mixing machine for compressed wood pallet block production

The process of mixing the dried wood chips and glue during the production of wooden pallet blocks is called the glue mixing process. The quality of the glue and the ratio of the glue directly determine the quality of the wooden pallets feet.

The working principle of the glue mixing machine

After the wood is added to the barrel of the glue mixer machine, a main shaft in the barrel drives the blade to rotate, and the blade on the blade drives the wood added with glue to rotate and turn along the barrel wall. The material is constantly turning in the barrel, and the glue and the material are mixed with each other. Through such high-speed rotation, the materials are mixed quickly, preparing for the next step of the production of wood pallet legs.

wood pallet block making machine

The pallet block machine mainly uses wood chips to produce wood blocks. After the wood chips are dried by a dryer and mixed with glue, they are transported to the pallet block-making machine. The wood pallet block machine is hot-pressed to form the pallet block at a time. The wood chips are formed by high temperature and high pressure in the machine, and the pallet block is extruded through the mold.

About Us

We are professional manufacture of hot press pallet block machine. The new type pallet block production line designed and manufactured by our company has been upgraded for 4 generations according to our customers’ feedback and our design technology. We are also a professional export company in China, We can provide you with professional services.

.