What Is a Sawdust Block Making Machine?

A sawdust block making machine is specialized equipment used to compress sawdust and other wood residues into solid blocks. These blocks are often used as components in wooden pallets or as fuel briquettes. The machine transforms loose sawdust into dense, durable blocks through a process involving compression and sometimes heat or adhesives.

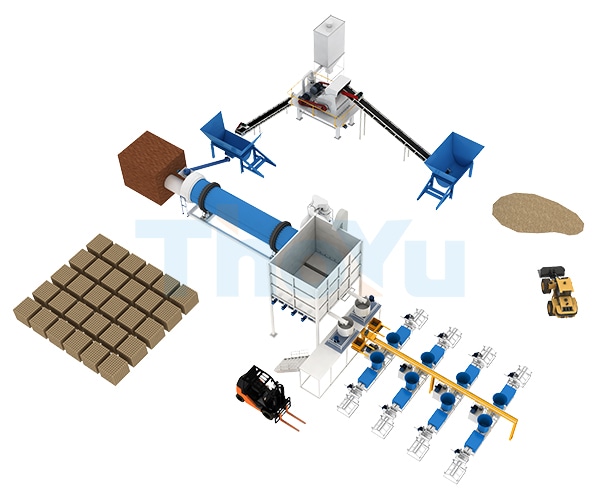

How Does a Sawdust Block Making Machine Work?

- Chipping: The materials are pre-sorted and shredded to the desired chip size.

- Foreign material removal: All foreign material and non-wood content is removed by means of industrial scanners and magnet technology.

- Drying: Through drying machine to desired final moisture content of less than 5%.

- Glue addition: Mixing of coarse and fine chips, addition of glue and hardener.

- Extruding: The materials are fed into a moulding chamber, after high temperature and pressure, the blocks are extruded.

- Inspecting: The blocks are inspected for quality to ensure it meets the required standards for strength, size, and durability.

Benefits of Using a Sawdust Block Making Machine

- Waste Utilization: Efficiently recycles sawdust and wood waste, reducing the need for disposal and promoting sustainability.

- Cost-Effective: Reduces material costs by utilizing waste products and decreasing dependency on solid wood.

- Consistency: Produces blocks with uniform size and quality, essential for standardized applications like pallet production.

- Versatility: Can produce blocks for various uses, including pallet components, fuel briquettes, and more.

- Environmental Impact: Supports eco-friendly manufacturing practices by reducing waste and utilizing renewable resources.

Sawdust block making machine is a valuable tool in the woodworking and recycling industries. It transforms sawdust into useful, high-quality blocks, contributing to both economic efficiency and environmental sustainability.