plastic pallet injection machine|plastic pallet press equipment

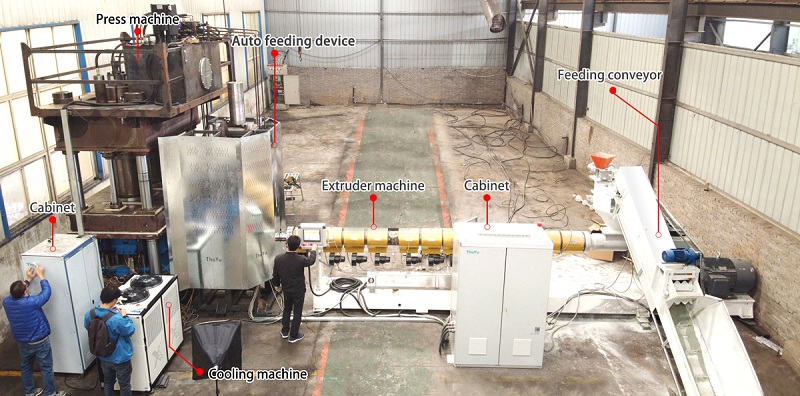

The plastic pallet production line mainly uses plastic or composite materials to produce plastic products. The plastic pallet-making machine is an important part of the plastic pallet production line. According to the types of raw materials it does use, it can produce a variety of plastic products. We are professional suppliers and plastic recycling machine manufacturers in China. we provide customers with a new type of waste recycling solution that can produce molded plastic pallets with low cost and environmental protection. The raw materials suitable for the machine can be waste plastics, PP, PE, PVC, etc. The produced plastic pallets can be used for packaging or as a load for inventory. Meanwhile, plastic pallets are good for reusing waste plastics and are environmentally friendly. We use waste recycling technology, adopt a unique plastic recycling process, so the plastic pallet-making machine price is low and affordable.

The main structure and details of the plastic pallet making machine

Frame part

The upper and lower beams and sliding parts of the machine are made of integral steel castings, which will not be deformed or damaged after long-term use; the surface of the column is plated with hard chrome, which is wear-resistant and will not rust.

Hydraulic system

The injection molding pallet press adopts the hydraulic system designed by our company, the plastic pallet moulding machine can run smoothly, provide sufficient pressure, and there is no hydraulic shock during operation; our company uses high-quality hydraulic components to increase the service life of the equipment; the plastic pallet injection molding machine uses high-quality high-pressure oil pipes to avoid equipment leakage.

The electrical system

The plastic pallet manufacturing equipment uses PLC programmable controller to control the operation of the machine. Use the buttons on the machine to control the start and stop of the compressed plastic pallet equipment. According to the equipment working environment and related requirements, the technical parameters can be adjusted on the LCD screen.

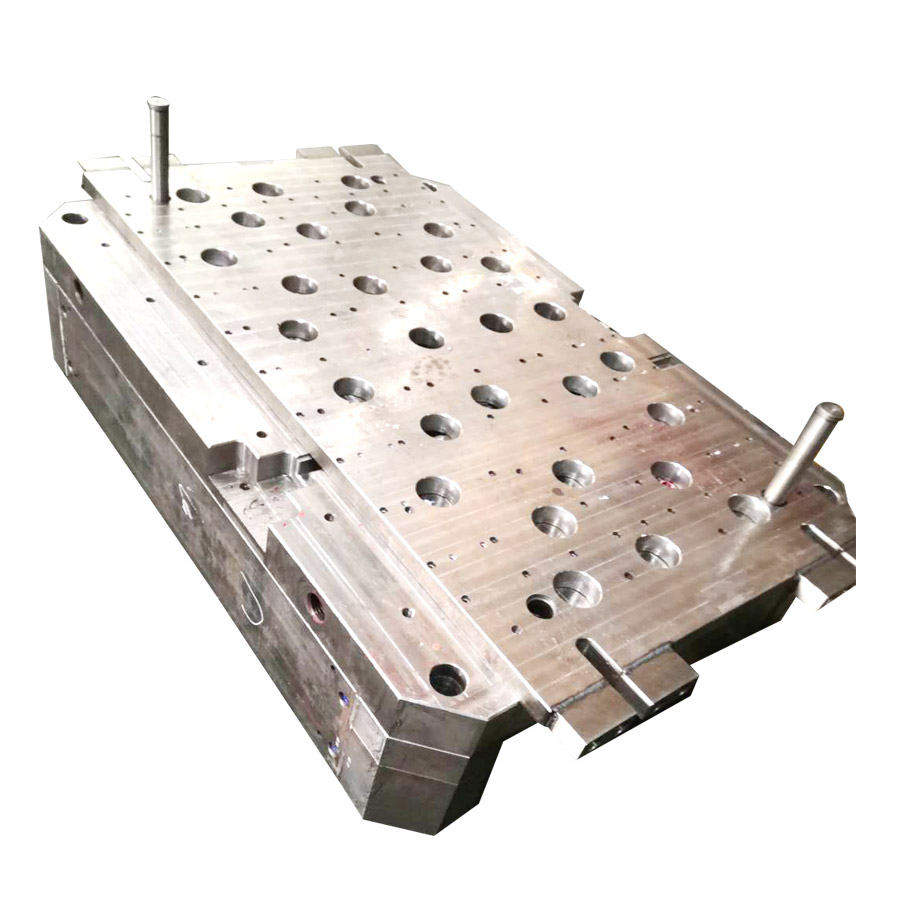

plastic pallet injection molding machine’s forming pallet mold

The mold part of the plastic molding machine for sale is made of high-quality wear-resistant monolithic steel, which is milled by a high-precision milling machine. The machine not only has high precision, but also all parts are wear-resistant. Some parts that are easy to wear can be disassembled, reducing replacement costs.

The working principle of plastic pallet making machine

The worker puts the extruded plastic into the mold above the machine. When the pressure plate enters the mold cavity, the main cylinder enters the pressure oil, and the main cylinder begins to compress the material. After maintaining the compression for a period of time, the main cylinder retreats slightly, the auxiliary cylinder enters the oil, the piston rod retreats and resets, completes a cycle of compression molding the plastic pallet, and begins to prepare for the next cycle.

Raw materials and finished products of plastic pallets

The raw materials of plastic pallets can be PS, PP, LDPE, PVC, HDPE, PET, and other plastics, as well as most waste plastics.

Technical Parameters of Plastic Pallet Molding Machine

Plastic Pallet Molding Machine

| Model | PM-1000 |

| Pressure | 0-1000 tons (adjustable) |

| Number of hydraulic cylinders | 2 |

| Molding cycle | 120 seconds |

| Output | 720 pieces/24 hours |

| Power | 43.6 kW |

| Weight | 30 tons |

Characteristics of plastic pallet molding equipment

- We have updated the traditional equipment and redesigned it based on the original machine to produce plastic pallets for various industries. The production line adopts new compression molding technology, which can greatly reduce the cost of raw materials.

2. In the process of production and processing, it can be fully automated, and the machine can carry out long-term, stable, and efficient automatic control. Our redesigned machine makes the pallet manufacturing process more stable.

3. In the process of production and processing, the price of raw materials is lower than 50% of the raw materials for traditional plastic pallet production, and the production cost is also lower than 50%. In addition, the process flow of the plastic pallet production line is easier and easy to operate.

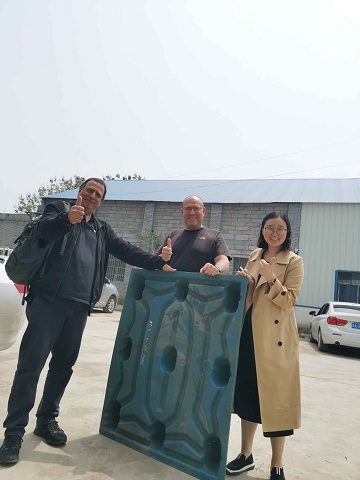

Why Choose ThoYu

We also provide a variety of plastic recycling machines to make full use of resource recycling technologies to protect the environment. The price of the machine has a very big competitive advantage in the plastic recycling industry. We can provide the most advanced plastic recycling technology according to the needs of customers, improve the recycling rate, and reduce the customer’s production costs. At the same time, we provide professional plastic molded pallet production solutions to reduce the price of the machine. Compared with the same industry, our machines are very competitive in price and quality.