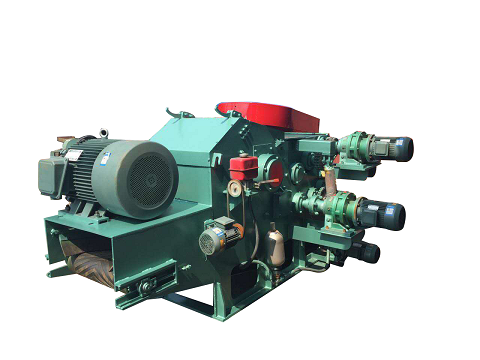

drum wood chipper for sale|industrial wood chipper

The drum wood chipper machine is a kind of wood chipper produced by ThoYu company. This machine is an improvement on the original chipper, specifically for processing various wood materials. The drum wood chipper machine processes a wide range of raw materials, which are widely used in papermaking, particleboard, fiberboard, and wood flour processing industries. It can cut logs, small diameter wood, branches, sticks, boards, and other materials into wood chips with uniform length and flat cuts. The wood chips processed by the drum wood chipper are of high quality, and the wood chips are flat and uniform in size.

Introduction of drum chipper machine

Drum chipper is special equipment for producing wood chips. This product is widely used in various wood processing factories. The drum wood chipper produced by our company has advanced structure, high quality of cut wood chips, and convenient operation and maintenance of the machine. The main raw materials for machine cutting are small-diameter wood and leftovers from wood harvesting and processing (such as branches, slabs, slats, round wood cores, waste veneers, etc.)

Structure of industrial wood chipper

The structure of the drum wood chipper is not too complicated. The drum wood chipper consists of a body, a knife roller, an upper and lower feeding mechanism, a conveyor belt, and a hydraulic system. The machine body is welded with high-strength thick steel plates to support the entire machine to withstand certain vibrations. Two to four flying knives are installed on the knife roller. The flying knife is fixed on the knife roller by professional flying knife bolts and pressure blocks. The drum wood chipper cuts a wide range of raw materials and can cut wood of different thicknesses. The upper feed roller can float up and down within a certain range with the help of a hydraulic system to cut raw materials of different thicknesses. The cut qualified pieces fall through the screen holes and are discharged from the bottom. Large pieces will be cut in the machine.

Working principle of drum wood chipper

The wood is transported by the conveyor system and enters the drum wood chipper through the feeding port. Under the shear of the high-speed rotating flying knife and the bottom knife mounted on the machine base, the wood is cut into wood chips. A screen is installed under the knife roll, and the mesh size of the screen can be adjusted according to customer needs. The cut qualified wood chips leak through the screen holes and are output through the conveying system. Because a small amount of larger wood chips cannot pass through the mesh of the screen, they continue to be driven by the rotating knife roller and hit the crushing rod to be broken again.

Application fields of drum wood chippers

Drum wood chipper is a machine that cuts the wood into wood chips, such as: waste wood, branches, wood, sugar cane, and other wooden materials.

1.The wood chips cut by the drum wood chipper can be used in the field of board processing, such as medium density board, particleboard, wood fiberboard, artificial board, etc. These board processing plants have a large demand for wood.

2.The wood chips cut by the drum wood chipper can be used in papermaking and other fields. After cutting wood into wood chips, it can be used as raw material for papermaking.

3.The cut wood chips can be used in power plants, boiler plants, biomass pellet plants, and other places to provide heat as fuel.

4.The drum wood chipper can be used in the production line of molded wooden pallets. The raw material is crushed into a certain length of wood chips by a drum chipper and then enters the dryer to dry the excess water.The dried wood chips are added with glue and fully mixed with them, and then the mixed materials are put into the wooden pallet press for hot pressing, and after the hot pressing, the molded wooden pallet can be taken out.

The performance advantages of drum wood chippers

1.Strong adaptability: Because the drum chipper adopts integrated assembly technology, it can be installed and used under different geographical and topographical conditions. At the same time, the operation of the machine is not affected by the season, climate, and other external conditions.

2.Save time: Because the drum chipper does not need to make a foundation, it can save users 10-15 days. After the equipment is delivered, it can be installed and put into production immediately, usually within 1-2 days.

3.Flexible and convenient: the installation and debugging of the drum wood chipper is very simple, which greatly improves the installation speed.

Technical parameters of drum wood chipper

| model | TY213 | TY215 | TY216 | TY218 |

| Diameter of fly roller (mm) | 300 | 500 | 650 | 800 |

| Number of flying knives (hands) | 2 | 2 | 2 | 2 |

| Inlet size (mm) | 120*300 | 140*400 | 180*500 | 225*680 |

| Knife roll speed (rev/min) | 730 | 592 | 59/830 | 650 |

| Feeding speed (m/min) | 38 | 37.4 | 37 | 37/25 |

| Machinable maximum diameter (mm) | 90 | 105 | 120 | 160 |

| Wood chip length (mm) | 26 | 30 | 30/22 | 30/20 |

| capacity (cubic meters/hour) | 3-5 | 4-5 | 10 | 15-20 |

| Main motor power (kW) | 30 | 45 | 55 | 110 |

| Weight (kg) | 1200 | 2900 | 4070 | 7000 |

| Dimensions (mm) | 3680*870*900 | 3421*1790*1060 | 4348*1730*1258 | 4678*2150*1500 |

Our company’s service and support

As a professional manufacturer of wood processing solutions, in order to improve the quality of the drum wood chipper, we welded the body of the drum wood chipper with high-strength steel plates. This ensures that the supporting parts of the whole machine are strong and durable. We have a professional installation team that can go abroad for installation according to customer needs. Our company will do long-term after-sales service for every machine you buy to ensure that every customer will be satisfied!