pallet legs nailer for sale |automatic pallet legs nailing machine

The automatic wood pallet legs nailer is an important piece of equipment in the European wooden pallet production line. It can nail wood strips and pallet blocks in advance. Put the cut wood and pallet legs on the automatic pallet legs nailing machine, and the wood pallet legs nailer can automatically connect the boards and the pallet legs. This can facilitate the pallet nailing machine to nail the entire European pallet. The European-style wooden pallets after being nailed by the automatic wood pallet legs nailer are firmer. The wooden pallet block nailing machine is mainly composed of two parts, one is the feeding part and the other is the nailing part. This machine has high production efficiency and can be operated by only one worker, saving labor costs.

Introduction of pallet legs nailing machine

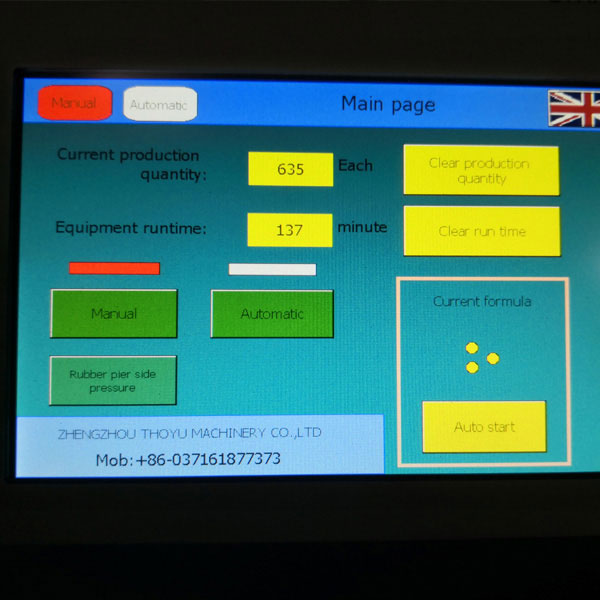

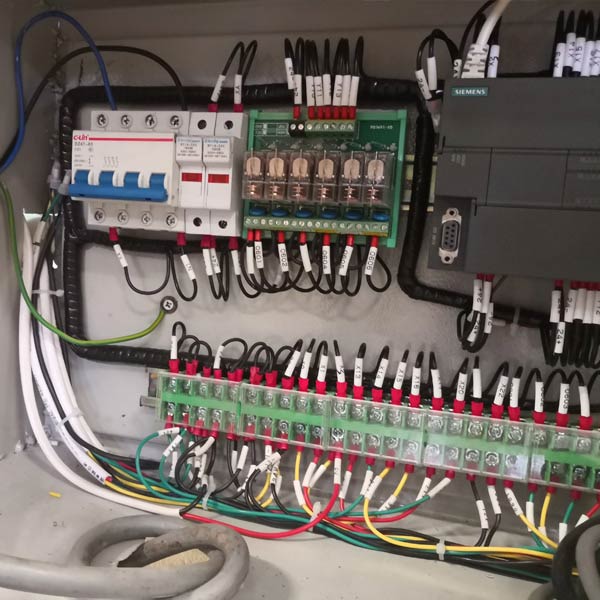

The wood pallet legs nailing machine can be divided into three pallet legs, four pallet legs, and five pallet legs according to the pallets that can be produced. Choose different models of machines according to customer needs. Automatic pallet legs nailer is for the professional production line of European standard pallets. The pallet block nailer machine produced by our company can nail all kinds of European standard pallets block, solid wood pallets block, and shaving pallets block. The machine has a wide range of applications, and each part can be adjusted according to the needs of customers in actual production. The machine is controlled by PLC during operation. The automated operation does not require human intervention. It can greatly improve work efficiency.

The structure and working principle of wood pallet legs nailer

The unloading part of the wooden pallet block nailing machine is driven by a chain. The wooden board moves under the nail gun, and then the nail gun nails the board and the wooden block. This machine can be customized in size according to customer requirements, and the normal size is below 1300 mm. The nail gun of the pallet feet nailing machine can use the brand specified by the customer, the number of nails can be adjusted, and the nailing position is neat. During the nailing process of the machine, there will be no problems with missing nails and weak nails.

Features of automatic wood pallet legs nailer

The wood pallet legs nailer is a machine specially designed by our company for European pallets. The machine has a high degree of automation, simple structure, and easy maintenance. The size can be adjusted manually or by the program on the machine. The operating system of the pallet feets nailer machine adopts PLC, and workers can operate it through the touch screen. The machine can be operated by one person, and workers can learn how to use the machine after three days of training. The nail gun adopts the Stanley brand, the position of nailing is determined by the servo motor and induction switch.

Technical Parameters of automatic wood pallet legs nailer

| Model | TYLN-1300 |

| Working flow | Manual feeding-Auto nailing |

| Operating mode | Touch screen control |

| Motor power | 0.75 kW servo Siemens motor |

| Weight | 1100 kg |

| Speed | 4-6 sec/leg |

| Production efficiency | 720 legs/h |

| Voltage | Customized |

| Bottom size | Adjustable |

Advantages of automatic pallet legs nailing machine

- This pallet legs nailing machine is easy to operate, and one person can operate the machine to automatically complete the feeding, pressing, nailing, fixed-length cutting, etc., with high efficiency.

2. The nails are uniform, the nails are on a parallel line, the length is the same, and the sawing cross-section is completely vertical.

3. When nailing, there is no gap between the layers and the height is consistent, and the quality of the product is greatly improved.

4. The processing surface is flat, and the size can be adjusted as required, saving costs.

Our pallet block in the pallet industry

This machine is a new type of equipment in the pallet industry. ThoYu company independently designed the pallet nailing machine based on years of experience. The electrical appliances use high-quality components, the operation is simple and easy to learn, and the process is not complicated. This equipment has become a necessary machine for European pallet manufacturers. If you want to know more, please contact us in time.