The production line of wood pallet block includes: crusher, dryer, glue mixer, pallet block press machine, cutting saw (received or automatic), automatic block cutting machine. Raw materials into the pulverizer crushed into wood chips, and then into the dryer drying, through the glue mixing machine, raw materials and glue mixing evenly, and then into the hot press abrasive hot extrusion molding.

Wooden pallet block press machine is mainly used to produce wood chips extruded wood blocks, the product is mainly used to replace the traditional wooden pallets used in the log foot block. The foot block machine using waste wood, wood chips, wood shavings as raw materials, dried by the dryer, and glue mixed evenly, a hot press molding extrusion blcok, with no chips, good waterproofing, strong nail force and other characteristics.

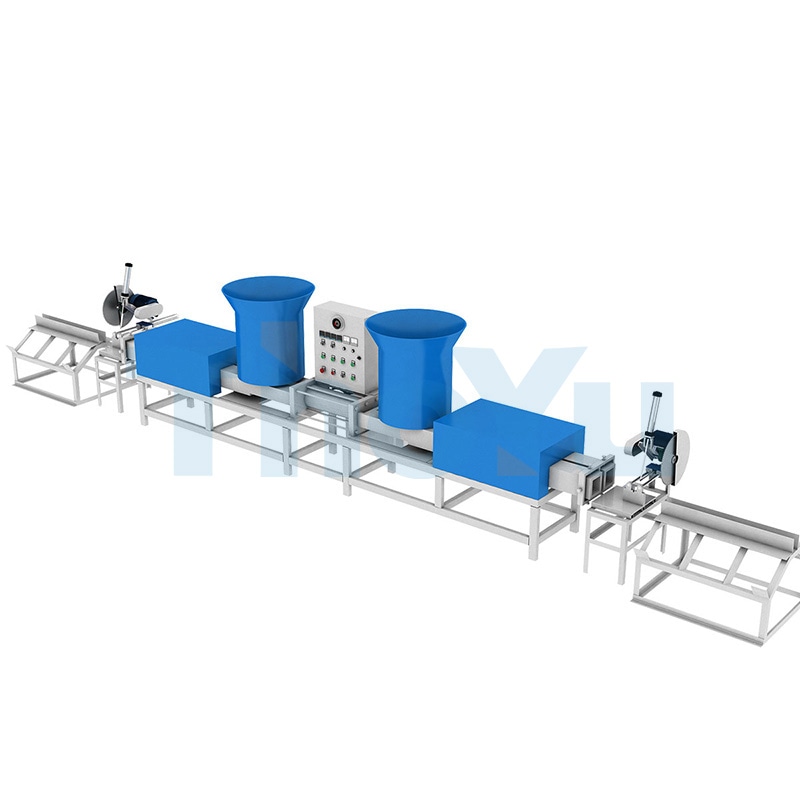

Wooden pallet block press machine according to its production type is divided into single-head, double-head and three types of three heads, the shape of the hopper is divided into square and round, the mold is made of stainless steel, can be more prolonged service life of the mold.

Wooden pallet block press machine performance characteristics

- A device can produce two different specifications of the type of foot pie.

- It can be produced by waste wood, wood shavings, edges and other raw materials, which can greatly save the cost of raw materials.

- Unique PLC control system, touch screen temperature display, alarm system.

- Pallet blocks are extruded by hot pressing, fumigation-free, convenient for export.

- Simple operation, one person can operate three machines, reducing labor cost.

- High degree of customization, can be customized shape, whether the middle with holes and other requirements