drum drying machine| rotary dryer | drum dryer

The rotary drum drying machine is a dryer that is widely used in industrial production. It has the advantages of high productivity, convenient operation, reliable operation, and low power consumption. The drum dryer is a common, large and medium-sized dryer equipment that can dry a variety of materials. Our company can provide matching rotary drum drying machines according to customers’ raw materials. According to the experimental results of different materials, our company continuously improves the structure, performance, and production capacity of the machine to meet the drying requirements of different customers. The rotary drum drying machine is widely used in food, feed, chemical, pharmaceutical, mining, and other industries, and is an indispensable machine in industrial production.

The introduction of the rotary drum drying machine

The drum dryer is a device that is heated by hot air, and the material is fully mixed with the hot air through a rotating cylinder, and the material in the cylinder is continuously dried. The rotary drum drying machine produced by our company has a large production capacity and can be operated continuously. At the same time, the machine has a simple structure, convenient operation, stable operation during work, and low maintenance cost. This drum dryer has a wide range of applications and can dry powder, granule, and block raw materials. And in the actual drying process, the machine allows large fluctuations in output without affecting product quality.

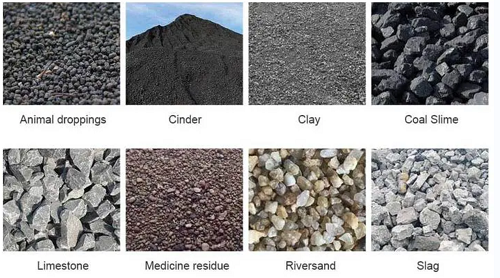

Materials that can be dried by the rotary drum drying machine

The drum dryer has a very wide range of applications and can meet the drying requirements of various industrial materials. Mainly used in the following industries.

1.Building materials industry: The raw materials used in construction and engineering mainly include sand, river sand, yellow sand, cement, clay, and turf soil.

2.Agriculture and forestry: distillers grains, straw, wood chips, and sawdust, etc.

3. Industrial industry: drying industrial products or by-products, such as drying waste paper pulp, plastic garbage, desulfurized gypsum, fly ash, and industrial sludge.

4. Mineral processing industry: coal slime, lignite, cinder, flotation coal, etc. in the coal processing industry; ore, slag, slag, copper ore, laterite nickel powder, tailings, etc. in the smelting and processing industry; sand and gravel industry Quartz sand, limestone, active lime, etc.

5. Livestock industry: animal manure such as pig manure, cow manure, and chicken manure.

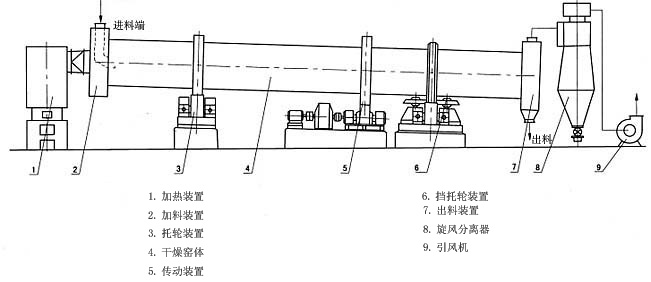

Structure of rotary dryer

The rotary drying machine is similar in structure to other dryers and is mainly composed of a rotating body, a lifting plate, a transmission device, a support device, and a sealing ring. The drum is a slightly inclined cylinder, the material is added from the higher end, and the hot air enters the cylinder together with the material. With the rotation of the tumble dryer, the material moves to the lower end due to gravity. A copy board is installed on the inner wall of the cylinder to pick up and sprinkle the material to increase the contact surface between the material and the airflow and increase the drying rate. The dried product flows out from the bottom end of the tumble dryer.

1.Cylinder body; 2. Front roller ring; 3. Rear roller ring; 4. Gear; 5. Stop roller (not applicable for small dryers); 6. Drag roller; 7. Pinion gear; 8. Discharge part; 9.Lifting board

Working principle of the drum drying machine:

The wet material is sent to the hopper by a belt conveyor or bucket elevator and then enters the drum dryer through the hopper. The drum of the drum dryer is a slightly inclined rotating drum. The material is added from the higher end and flows out from the lower end after heating. With the rotation of the cylinder, the material moves to the lower end under the action of gravity. When the wet material moves forward in the drum dryer, it is fully mixed with the hot airflow, and the wet material can be dried.

The heated material flows out at the discharge port and then is sent out via a belt conveyor or a screw conveyor. The rotation speed of the rotary drum drying machine can be adjusted. According to the humidity of the material and the particle size of the material, the speed of the drum dryer and the flow rate of the hot air is adjusted. This can better remove the moisture of the material and achieve the best drying effect.

characteristics of rotary dryer

1.The design of each part of the drum dryer is reasonable, the performance is reliable, and the heat utilization rate is high. The materials are dried evenly in the machine, the machine is not easy to be damaged and the maintenance is convenient.

2.The drum dryer is specially designed with a retaining wheel structure, which greatly reduces the horizontal thrust caused by the inclination of the equipment. Strong anti-overload capability, smooth running of the drum, and high reliability.

3.The rotary dryer has the characteristics of high-temperature resistance and can use high-temperature hot air to quickly dry the material. The scalability is strong, and the design considers the production margin, even if the output increases slightly, there is no need to replace the equipment.

4.The drum dryer has a large processing capacity and can process a large number of materials at a time. In the drying process, the fuel consumption is less and the drying cost is low.

Technical parameters of drum dryer

| Model (mm) | Inclination (%) | Speed (r/min) | Inlet temperature (℃) | Power (kw) | Production capacity (t/h) | Weight(t) |

| Ф600×6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| Ф800×8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| Ф800×10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| Ф1000×10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| Ф1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| Ф1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Ф1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Ф1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Ф2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Ф2200×14000 | 3-5 | 1.5-6 | ≤800 | 20 | 8-15 | 41 |

| Ф2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Ф2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

About Us

Our company has been committed to the development of the dryer industry. Mainly engaged in the research, development, manufacturing, and sales of manure dryers, sand dryers, slime dryers, and ore drying machines. If you want to choose an efficient and energy-saving drum dryer, please contact us.