European pallet production line|making European pallet

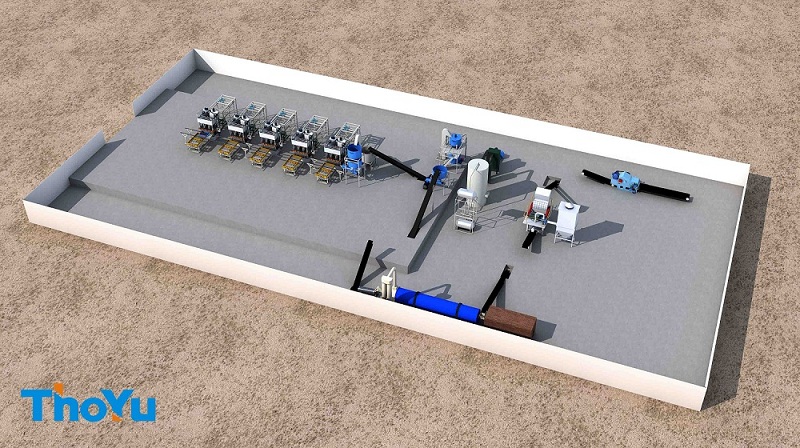

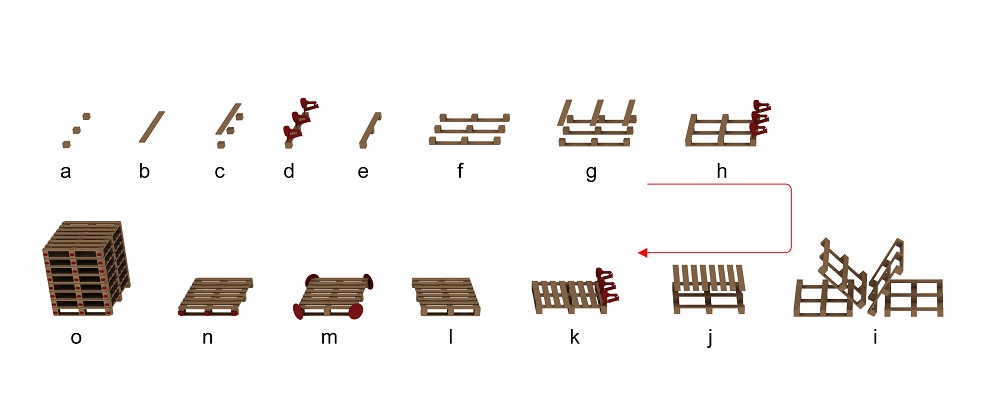

Common European wooden pallets are composed of panels and wooden blocks. The European wooden pallet production line processes wooden boards and blocks then connects them into European wooden pallets. European standard pallets can be inserted from four directions, making them more convenient to use in the logistics industry. According to the characteristics of European wooden pallets, The ThoYu has developed a professional European pallet production line. This production line is composed of a series of mechanical equipment. We carefully design every piece of equipment.

Dimensions of European wooden pallets

Choosing a suitable European wooden pallets size should match the size of the transportation tool. This can make full use of the space in the transportation tool and save transportation costs. Therefore, when choosing a wooden pallet production line, pay attention to the size of the European wooden pallets produced. The appropriate European wooden pallet size matches the size of the container and transport truck. Secondly, the size of the warehouse and the size of the goods should also be considered when choosing pallets, which can reduce unnecessary waste.

How to choose raw materials for wooden pallet production line

When using the European wooden pallet production line to produce pallets, you need to pay attention to the following points when choosing raw materials:

- The raw materials have a wide range of sources and are easy to obtain, usually solid wood, which is cheap.

- Light weight and high bending strength.

- The material can be sawn, planed, nailed, easy to process and easy to maintain.

- Strong adaptability to temperature and wide application area.

- Recyclable and renewable.

European wooden pallets are usually made of solid wood, and the raw materials should be suitable for processing on the European wooden pallet production line. There are mainly poplar, metasequoia, pine, and miscellaneous wood. From the perspective of cost, poplar wood is more common, the price is right, and the strength is also acceptable. The strength of Metasequoia is not as good as others, but it is suitable for making wooden pallets with low load-bearing capacity.

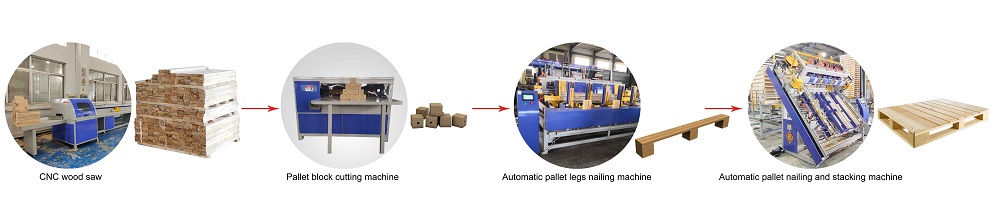

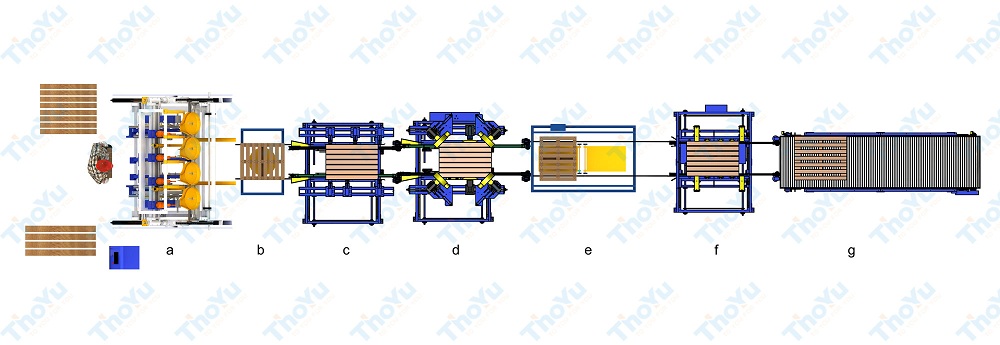

Production process of European pallet production line

CNC wood saw in European pallet production line

When producing European-style wooden pallets, the control panel on the wood CNC saw can be adjusted to determine the length of wood cutting. It is mainly used for processing wooden pallet boards and pallet foot piers. Compared with ordinary manual cutting, the wood CNC cutting saw can be mass-produced when applied to the European pallet production line, which improves the processing speed. This standardized production can make full use of raw materials, save manpower, and improve the production efficiency of European wooden pallets.

wooden block multi-blade cutting machine

The wooden block multi-blade saw is suitable for cutting wood pallet block, solid wood, and multi-layer wood. It occupies a dominant position in the European pallet production line. The machine runs stably and can run continuously and efficiently. At the same time, the production is efficient, the operation is safe, the machine can be disassembled.

automatic pallet legs nailing machine

The European-style wooden pallet continuous pier machine is an important equipment in the European-style wooden pallet production line. It can nail the boards and foot piers in advance. In the latter process, the nailing machine is used to nail the overall European pallet.

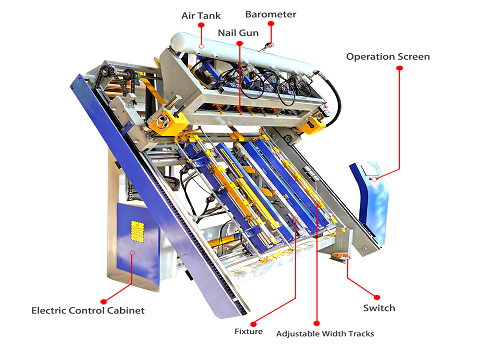

Pallet nailing machine in European pallet production line

The pallet nailing machine adopts advanced numerical control technology, which can adjust the nailing speed according to the processing capacity of the European-style wooden pallet production line. This nailing machine is suitable for the production of CP1-CP9 European pallets. For European pallets of the same type and different sizes, only need to adjust the fixture to produce, very convenient and fast.

Advantages of European wooden pallet production line

In the process of packaging and transportation of goods produced by enterprises, the use of European wooden pallets has always been more common. Therefore, the wooden pallets produced by the wooden pallet production line must have sufficient strength. This can ensure the integrity of the goods and effectively reduce the damage rate of the goods. At the same time, choose dry wood when selecting materials, which can prevent mildew and increase the service life.

High configuration of pallet production line

The pallet production line produced by our company adopts professional controllers and customized supporting software to ensure safe and stable operation and high production efficiency.

When manufacturing each machine, we use servo motors and precision servo reducers: the machine runs with high precision and ensures consistent working dimensions.

Can produce many types of wooden pallets

The European pallet production line can change the configuration of the machine to process American pallets. Special-shaped pallets can also be customized according to customer needs, and can also be made of square bar wooden pallets and square pier wooden pallets.

Single operation, simple process, high production efficiency

It is operated through the touch screen, the program controls the automatic nailing, the nail gun speed is 4 times per second, and the feeding speed is 400 pieces/8 hours, which is 3 times that of manual. Manual feeding, automatic nailing, automatic palletizing, pneumatic pressing.

About ThoYu

ThoYu company is a professional manufacturer of pallet machinery and also provides customers with pallet production technology. Our wooden pallet production line can greatly improve production efficiency, and one worker can operate the entire production line. At the same time, the European-style wooden pallets produced are of high quality and are very popular in the market. If you have the idea of producing wooden pallets, please feel free to contact us.